CASE STUDY

Humidity Stabilisation in a Metrology & Calibration Facility

When uncontrolled fresh air intake disrupted calibration accuracy and laboratory throughput.

Unstable humidity conditions were preventing a calibration and measurement laboratory in Singapore from operating reliably. Relative humidity frequently rose to levels that exceeded acceptable limits for sensitive calibration and measurement work, forcing delays and reducing the laboratory’s ability to complete jobs on schedule. Although cooling systems and dehumidifiers were already installed, environmental conditions remained unpredictable. Kruger was engaged to diagnose the root cause of the humidity excursions and restore the stable conditions required for accurate measurement and consistent laboratory operations.

THE RESULTS

~20% RH Reduction

Peak humidity levels reduced from approximately 90% RH to around 70% RH after corrective adjustments

Measurement Downtime Reduced

Fewer interruptions caused by humidity excursions, improving scheduling reliability

Targeted System Optimisation

Environmental stability achieved by correctly configuring existing systems and installed dehumidifiers, avoiding unnecessary over-specification

THE CHALLENGE

Environmental Instability in a Precision Measurement Environment.

Calibration and measurement laboratories handle high-value, humidity-sensitive instruments where environmental stability directly affects accuracy and traceability. In this facility, relative humidity routinely exceeded acceptable operating thresholds, particularly during certain periods of the day.

Data showed that humidity inside the laboratory occasionally rose higher than outdoor conditions, indicating that the issue was not simply ambient climate but something internal to the building systems. When humidity exceeded tolerance, calibration and measurement work had to be paused, delaying turnaround times and affecting service commitments to clients.

Despite having air-conditioning and dehumidification in place, the laboratory continued to experience humidity excursions that disrupted daily operations.

THE ASSESSMENT

Using Dew Point to Isolate the True Source of Humidity.

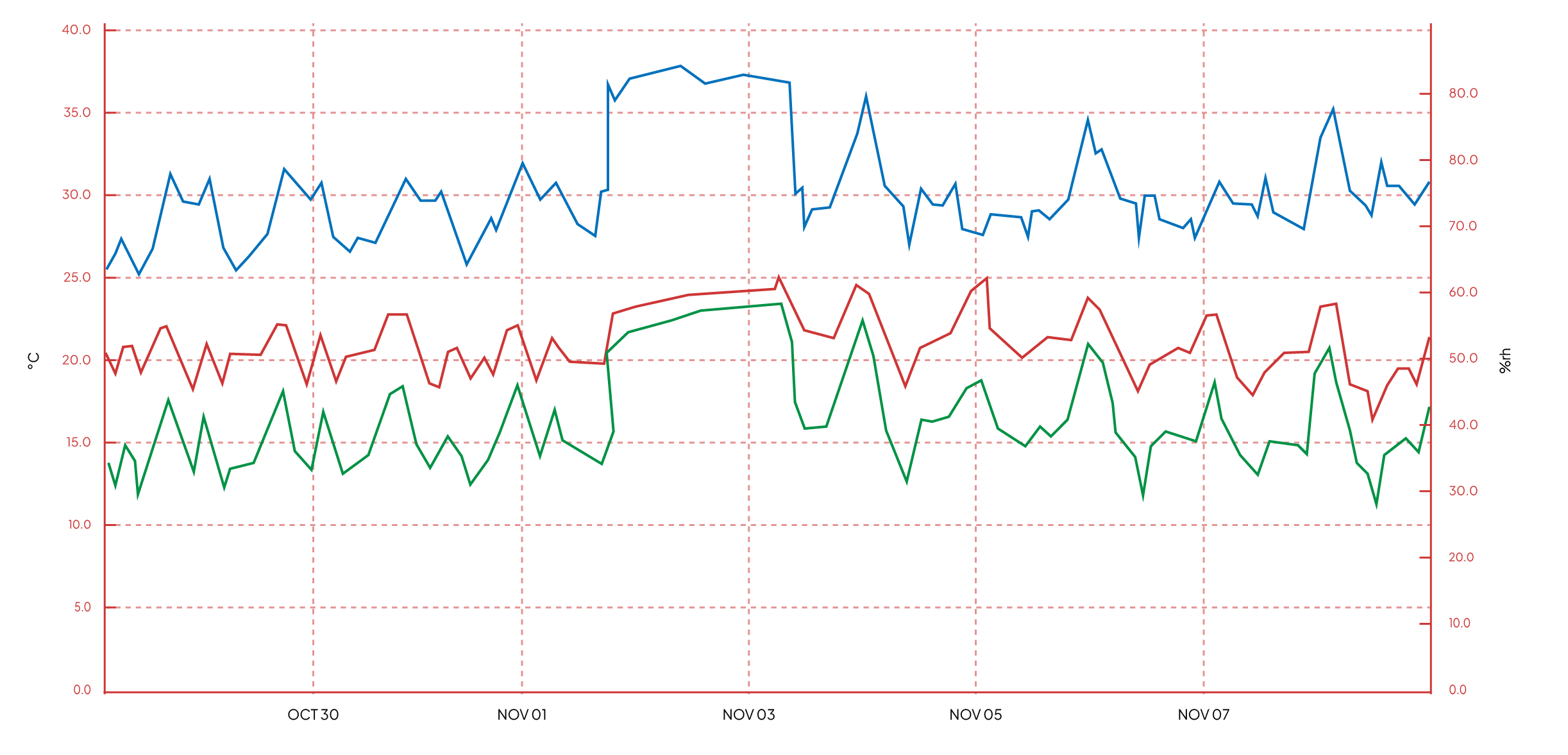

ABC Calibration Lab (pre-adjustment) KRS240X3

Celsius

Dew Point

Humidity

Kruger conducted a detailed on-site assessment supported by continuous data logging of temperature, relative humidity, and dew point. Rather than interpreting RH values in isolation, the team analysed how these variables moved together over time.

This analysis revealed a critical insight. During humidity spikes, dew point levels also increased, confirming that actual moisture was being introduced into the space, not merely that relative humidity was rising due to temperature changes. This distinction was essential in identifying the true source of the problem.

Further investigation traced the moisture load to excessive fresh air intake. Warm, humid outdoor air was being introduced into the laboratory continuously, far beyond what was required for occupancy or air quality. As this air was cooled, its moisture content remained, causing relative humidity inside the space to rise sharply.

KRUGER’S SOLUTION

Right-Sizing Fresh Air and Humidity Control to Actual Operating Needs.

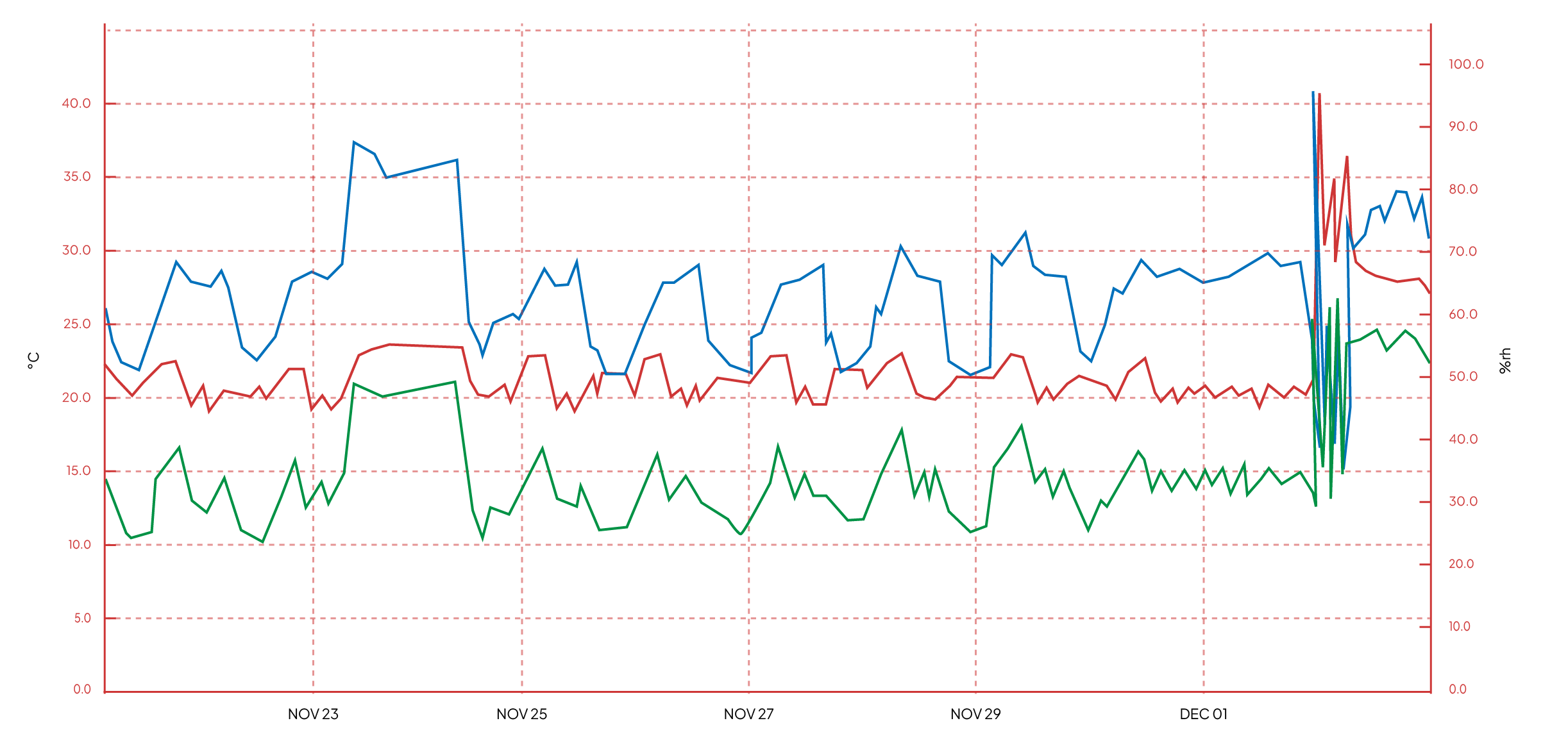

ABC Calibration Lab KRS240X3 Rear

Humidity

Dew Point

Celsius

Rather than recommending additional dehumidification equipment, Kruger proposed corrective adjustments to how fresh air was managed. Fresh air intake was right-sized and re-sequenced to align with actual occupancy and operational requirements.

Continuous fresh air supply was replaced with short, high-intensity purge cycles, maintaining indoor air quality while significantly reducing unnecessary moisture ingress. This approach limited the amount of humid outdoor air entering the space without compromising ventilation standards.

No changes were made to the number or placement of dehumidifiers. The improvement came from addressing the source of the moisture load, not treating the symptoms.

Kruger worked closely with on-site personnel to implement the adjustments and validate results through follow-up monitoring.

SOLUTION DEPLOYMENT

Diagnostic-led Consultation Process

Based on detailed environmental monitoring and dew point analysis, Kruger identified how existing ventilation behaviour was introducing excess moisture into the laboratory. Dehumidification capacity was then configured and deployed to support the corrected ventilation strategy, ensuring stable humidity control under real operating conditions rather than relying on blanket capacity increases.

THE IMPACT

Identifying the Root Cause to Restore Laboratory Operations.

Post-adjustment data showed a clear improvement in environmental stability.

Peak relative humidity levels were reduced from approximately 90% RH to around 70% RH, with fewer and less severe excursions.

With humidity kept within a more predictable range, calibration and measurement activities could proceed with fewer interruptions. Downtime caused by environmental instability was reduced, improving throughput and scheduling reliability. Crucially, these gains were achieved without additional capital expenditure, reinforcing the value of diagnosis-led intervention.

WHY IT MATTERS

In calibration and measurement laboratories, humidity control directly affects accuracy, throughput, and service reliability.

This case illustrates that humidity problems are not always solved by adding equipment. Without proper diagnosis, facilities risk unnecessary capital expenditure while the underlying issue remains unresolved. Kruger’s consultative approach ensures that humidity control strategies address the true source of risk, restoring environmental stability efficiently and cost-effectively.

Talk to Singapore’s Humidity Control Experts.

Whether you’re managing an industrial facility or improving your home environment, Kruger provides in-house engineering, local servicing, and expert consultation at every step.

Start with a free humidity assessment and trial unit, and experience why Kruger is trusted by Singapore’s industries and homeowners alike.