Our Manufacturing & Quality Process

Built with Swiss precision. Assembled with Singapore’s expectations. Trusted across Asia’s climate.

Every Kruger dehumidifier begins long before assembly. It starts with engineering discipline, rigorous sourcing, and a full in-house quality process that many competitors outsource. This gives you a product designed for decades of dependable use in Singapore’s challenging humidity.

Our approach is simple: meticulous care at every step, and control over every detail.

The Kruger Quality Loop

The Kruger Quality Loop is the framework that guides how every product is conceived, designed, manufactured, and validated.

It is a continuous process that ensures:

This disciplined loop is the reason Kruger can offer Singapore’s only 3-year dehumidifier warranty and maintain consistent performance across industrial, commercial, and home environments.

The Kruger Quality Loop

The Kruger Quality Loop is the framework that guides how every product is conceived, designed, manufactured, and validated.

It is a continuous process that ensures:

This disciplined loop is the reason Kruger can offer Singapore’s only 3-year dehumidifier warranty and maintain consistent performance across industrial, commercial, and home environments.

Our Manufacturing Process

01

Market Understanding

We begin by understanding how each product will be used.

We consider extraction needs, noise expectations, installation conditions, and pricing requirements to ensure the product is appropriate for its intended environment.

02

Product Specification

Clear engineering specifications are defined before manufacturing begins.

These specifications guide structure, airflow efficiency, energy use, component tolerances, and service access, reducing variability and improving durability.

03

Component Sourcing

Components are sourced from reliable, pre-qualified suppliers.

Selection is based on performance stability, durability in high humidity, and long-term serviceability rather than lowest cost.

04

Incoming Quality Control

All components undergo inspection before entering production.

This confirms material quality, electrical compliance, dimensional accuracy, and readiness for assembly.

05

Prototype Development

Based on the initial requirements and selected components, we build functional prototypes.

These prototypes allow us to validate design assumptions, component compatibility, airflow behaviour, and overall system performance before any production decisions are made.

06

In-House Testing

Each model is tested internally before moving to production.

Testing covers extraction performance, airflow, energy use, noise levels, and service accessibility. Designs are refined if required.

07

Small-Batch Production

Approved models are produced in limited quantities to validate manufacturing consistency and early performance before scaling.

08

Market Validation

Pilot units are placed in real environments to confirm performance under actual operating conditions.

This step verifies stability, reliability, and service access beyond the factory setting. Once validated, the model enters full manufacturing.

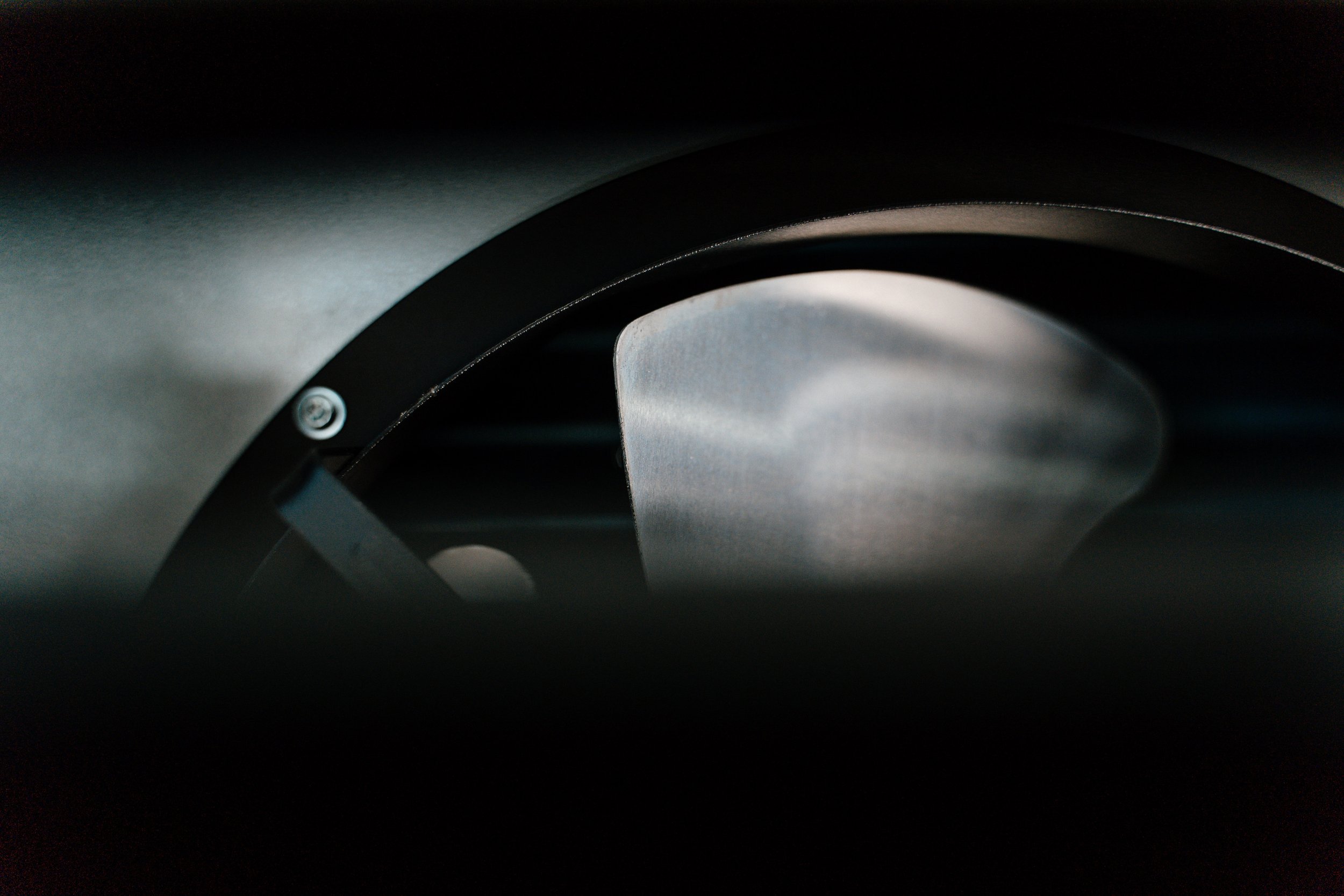

09

Manufacturing & Assembly

Production, final assembly, configuration, and factory testing are carried out in Thailand under controlled conditions. In Singapore, units are tested after servicing or repair to ensure performance is fully restored before redeployment. Each unit is assembled, electrically tested, run-tested, and inspected to ensure consistency.

10

Final Quality Check & Delivery

Before shipping, every unit undergoes final checks covering start-up, airflow, noise, and packaging integrity.

Only units that meet Kruger’s standards are released.

>400K

Units Manufactured

100%

Incoming QA/QC on Components

100%

In-Line Testing

During Production

Why This Matters

By controlling every stage of the process, Kruger delivers:

• Consistent Performance

• Faster in-house servicing

• Long Service Life

• Lower Lifetime Cost of Ownership

• Dependable Operation in Singapore’s Climate

Talk to Singapore’s Humidity Control Experts.

Whether you’re managing an industrial facility or improving your home environment, Kruger provides in-house engineering, local servicing, and expert consultation at every step.

Start with a free humidity assessment and trial unit, and experience why Kruger is trusted by Singapore’s industries and homeowners alike.